In high-pressure logistics environments, the right handling equipment isn’t just helpful — it’s mission-critical. Whether you're running a warehouse, a 24/7 fulfilment centre, or a retail distribution hub, the daily demands are intense: faster pick rates, tighter dispatch schedules, shrinking margins, and no tolerance for delays.

The equipment you rely on can make or break your operation. When pallets break, trolleys jam, or cages collapse, productivity stalls and safety risks spike. That’s why investing in handling products that are durable, space-smart, and optimised for multi-shift operations is a strategic move — not just a practical one.

Here are the top three must-have handling products that logistics pros are using to boost performance, reduce downtime, and cut out the waste — keeping things moving when every second counts.

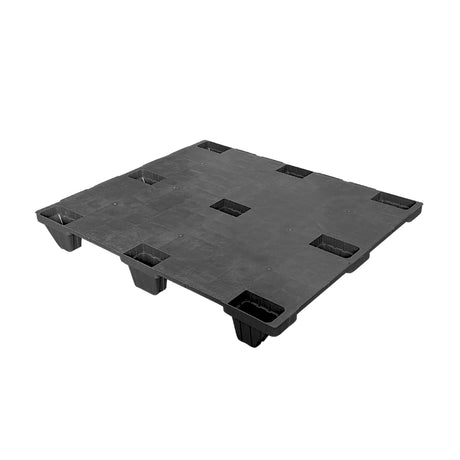

1. Heavy Duty Plastic Pallet

Heavy Duty Plastic Pallet

This is the strongest recycled plastic pallet on the UK market—made to thrive in demanding warehouse environments. Its 5-runner base provides stability under heavy loads, with impressive strength for static (5000kg), dynamic (1500kg), and racking (1000kg) applications.

- 1200x1000x155mm dimensions for Euro pallet compatibility

- Optional steel reinforcement for extreme weight handling

- Made from tough, recycled HDPE for eco efficiency

2. Euro Pallet Retention Unit

Euro Pallet Retention Unit

Keep loose, awkward goods secure and organised with this stackable steel retention cage. It folds flat for efficient returns, stacks up to four high, and has a half-drop gate for easy access without removing the unit.

- Fits 800 x 1200mm pallets perfectly

- Heavy-duty mesh and zinc plating for long-term durability

- Ideal for warehouse storage and transport

3. Nestable Cage Trolley on Wheels

Nestable Cage Trolley

Whether it’s a 3-sided, 4-sided, or full mesh model, this robust roll cage trolley is a workhorse for stock handling. Popular with supermarkets and warehouses, it features a space-saving A-frame and smooth wheels for easy manoeuvrability in tight spaces.

- Nestable design for efficient returns

- Noise-reducing hinges for quieter handling

- Built to perform in retail and distribution operations

Top Benefits for the Logistics Industry

- Efficiency: Compatible with forklifts, conveyors, and racking for smooth handling and dispatch.

- Space optimisation: Nestable and foldable units reduce clutter and increase return-trip payloads.

- Durability: Tough materials handle bulk loads without breaking a sweat.

- Sustainability: Recycled HDPE and reusable metal units reduce packaging waste.

- Safety: Stable designs and ergonomic features support safer, faster workflows.

Common Logistics Problems – and G-Force Solutions

Problem: Damaged or Weak Wooden Pallets

Solution: Switch to recycled heavy duty plastic pallets that last longer, carry more, and comply with hygiene and racking standards.

Problem: Inefficient Reverse Logistics

Solution: Our nestable trolleys and fold-flat pallet cages minimise space during returns and off-peak storage.

Problem: Stock Spillage and Unstable Loads

Solution: Euro pallet retention units keep everything contained, reducing damage and improving site safety.

Problem: Bulky, Non-Nestable Equipment

Solution: Choose stackable and nestable units that adapt to daily use without hogging floor space.

Problem: Manual Handling Injuries or Downtime

Solution: Our products are built with smooth wheels, ergonomic grips, and no-fuss mobility for safer handling shifts.